A research team from ETH Zurich, PSI, and Caltech has developed a novel thermochemical reactor that uses sunlight to convert carbon dioxide and water into precursors of gasoline at an unachieved efficiency. The feat is a breakthrough toward using solar energy to produce much-needed liquid fuels more efficiently. The process also does not produce any new carbon dioxide.

Search for Energy Carrier

Scientists ask themselves: how can we get hold of the vast, yet intermittent and unevenly distributed, solar energy resource such that it can be stored and transported from the sunny and uninhabited regions of the earth’s sunbelt to the world’s industrialized and populated centers, where much of the energy is required?

This question has motivated the search for recipes to transform sunlight into chemical energy carriers in the form of storable and dispatchable liquid fuels, such as gasoline and jet fuel, usable to propel not only our cars, airplanes and ships, but the entire world economy. This would ensure the goal of a sustainable energy future.

New recipe and cooking pot

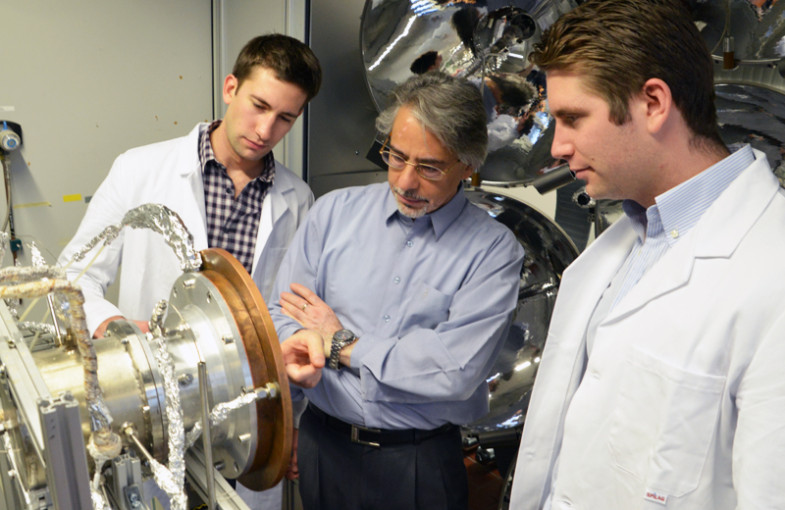

A research team around Aldo Steinfeld, Professor of Mechanical and Process Engineering at ETH Zurich and Head of the Solar Technology Laboratory at Paul Scherrer Institute, in collaboration with the California Institute of Technology (Caltech) in Pasadena, USA, has recently developed a promising recipe and associated reactor technology.

Their idea is based on a solar-driven thermochemical cycle for splitting CO2 and H2O using metal oxide redox reactions. “The operation at high temperatures and the utilization of the entire solar spectrum provide a thermodynamically attractive path to solar fuel production at high kinetic rates and energy conversion efficiencies”, says Steinfeld.

The solar reactor consists of a cavity-receiver with a small windowed aperture for the access of concentrated solar radiation. The selected dimensions ensure multiple internal reflections and efficient capture of incoming solar energy. A porous, monolithic ceria cylinder is placed inside the cavity and subjected to multiple heat-cool cycles under appropriate gases to induce fuel production.

Efficient heat transfer

With this arrangement, the porous ceria cylinder is directly exposed to concentrated solar radiation impinging on its inner walls, providing efficient radiative heat transfer directly to the reaction site. Reacting gases flow radially across the porous ceria cylinder, while product gases exit the cavity through an axial outlet port.

Experimentation was carried out at PSI’s High-Flux Solar Simulator with a 2000 Watt solar reactor prototype subjected to solar concentration ratios exceeding 1,500 suns. The measured solar-to-fuel energy conversion efficiency, defined as the heating value of the fuel produced divided by the solar radiative power input, reached 0.8 percent.

“This efficiency value is about two orders of magnitude greater than the one observed with state-of-the-art photocatalytic approaches for CO2 dissociation”, says Philipp Furler, doctoral student in Steinfeld’s group, who is currently working on the reactor optimization with help of fluid mechanics and heat transfer simulation models. Efficiencies above 15 percent are attainable.

500 cycles without interruption

Beyond efficiency, material stability is a crucial criterion for a viable thermochemical process. Using the differential reactor system, 500 cycles of water dissociation were performed without interruption, yielding stable fuel production at constant rates.

In the meantime, Steinfeld and his team are currently focusing on optimizing the solar reactor technology with the aim of scaling it up for megawatt solar towers, such as those already applied commercially for electricity generation.

When asked about the timetable towards industrial implementation, he is cautious and rather conservative: “By 2020 we should be able to witness the first industrial solar fuel plants coming into operation”.

Read More »

The GPHG Grand Prix d’Horlogerie 2012 was held at the Grand Théâtre de Genève and was presented by Adriana Karembeu and Frederic Beigbeder, also, to take the place of the authorities of the Canton of Geneva, he was also attended by Councillor Alain Berset. As with the last , to the delight of watch lovers around the world , the event was broadcast ” live ” – with an interpreter in English via web streaming from the website Euronews.org – media that has confirmed his interest in event Grand Prix d’ Horlogerie , the event that rewards the most beautiful watches of 2012.

The GPHG Grand Prix d’Horlogerie 2012 was held at the Grand Théâtre de Genève and was presented by Adriana Karembeu and Frederic Beigbeder, also, to take the place of the authorities of the Canton of Geneva, he was also attended by Councillor Alain Berset. As with the last , to the delight of watch lovers around the world , the event was broadcast ” live ” – with an interpreter in English via web streaming from the website Euronews.org – media that has confirmed his interest in event Grand Prix d’ Horlogerie , the event that rewards the most beautiful watches of 2012. History of GPHG Grand Prix d’Horlogerie

History of GPHG Grand Prix d’Horlogerie The Audience Award is chosen by those who voted for their favorite watches on the web sites of the ‘ event of World tempus , in addition to the public that he did in the evening during the event GPHG 2012.

The Audience Award is chosen by those who voted for their favorite watches on the web sites of the ‘ event of World tempus , in addition to the public that he did in the evening during the event GPHG 2012.